Gasoline And LPG Counterbalance Forklift: How To Keep The Gas Tank Safe

Oct 28, 2022Safety is the eternal topic of production, NEOlift as a manufacturer with more than 20 years of manufacturing experience, always pay attention to forklift safety, today NEOlift will talk about strengthening the safety of Gasoline And LPG Counterbalance Forklift guide.

LPG is superior to diesel and storage batteries in terms of versatility, reliability, efficiency and lower emissions. According to relevant data, forklifts fueled by liquefied petroleum gas in the United States account for about 90% of the market share of Class IV and V forklifts. Most managers abroad also prefer LPG for power rather than diesel or batteries, for example, 70% of internal combustion forklifts rated at 5,000-10,000 pounds abroad use LPG. About 50% are rated for tonnage of 10,000 or more. At present, the use of liquefied petroleum gas forklifts in China is relatively small, but also because of the relatively small share of liquefied petroleum gas forklifts, the use of liquefied petroleum gas forklifts safety has not attracted everyone's attention, so today we emphasize the use of liquefied petroleum gas forklifts safety is also crucial.

LPG is a non-toxic energy source that can be safely used anywhere, outdoors or indoors. This is because propane leaks do not damage the soil and have negligible effects on the ozone layer. Similarly, LPG spills do not pose an environmental hazard to drinking water or Marine ecosystems, while spilled gasoline can rapidly contaminate groundwater beyond drinking water health recommendations.

Propane is also colorless and almost odorless. For safety, an identifying scent has been added to the LPG so it is easily detected in the event of a leak. In addition, it is an approved clean fuel listed in the U.S. Clean Air Act of 1990, helping to provide cleaner, safer air for employees working near equipment. On the other hand, toxins released by diesel equipment have been shown to stimulate respiratory diseases, such as asthma, and are classified as carcinogenic by the World Health Organization.

LPG tanks are 20 times more puncture resistant than tanks containing ethanol, methanol or gasoline, and are made of carbon steel in accordance with procedures established by the American Society of Mechanical Engineers. Propane has the lowest flammability of all alternative fuels. Propane has a smaller flammability range than ethanol, methanol, hydrogen, and natural gas, reducing the likelihood of propane igniting accidentally in the event of a leak.

Special Safety Tips For LPG

Just like any heavy equipment, proper safety measures must be maintained when operating a propane forklift truck. In addition to general safety tips (such as wearing a seat belt, running at a safe speed, and keeping a safe distance from the edge of the ramp), there are some LPG specific handling requirements to keep in mind:

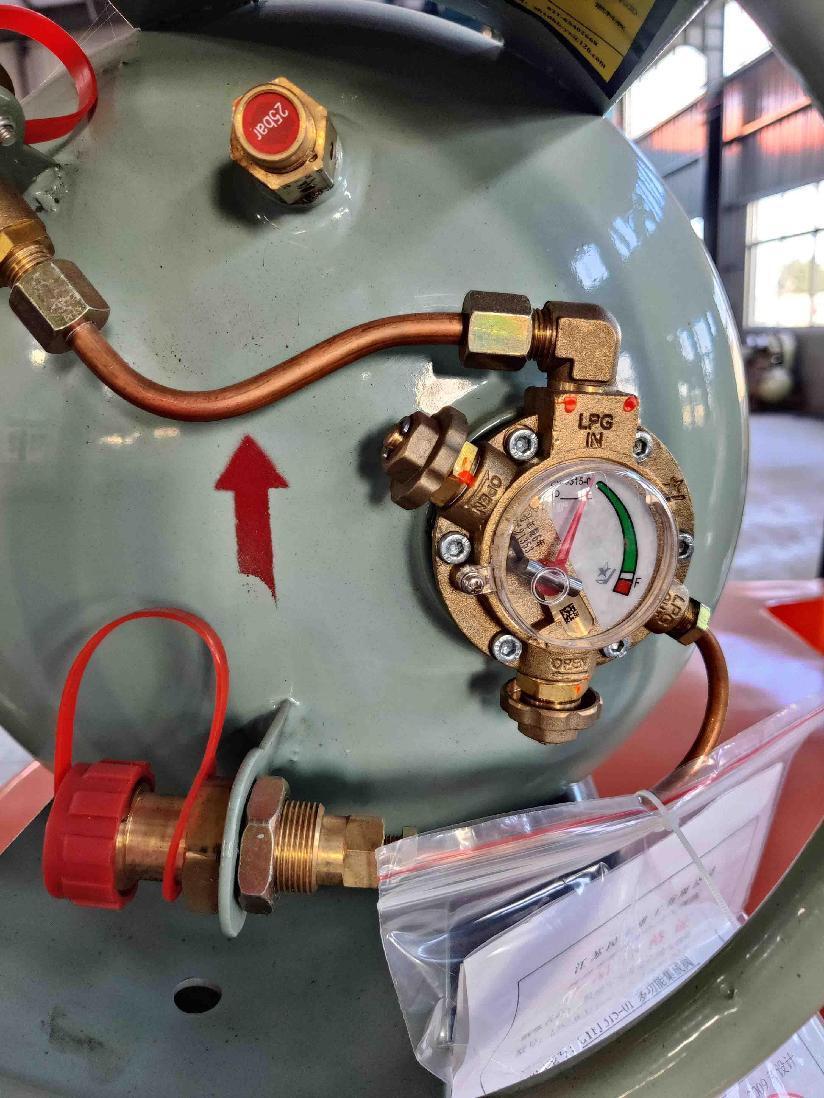

1.Check the LPG cylinder before operation. Check the cylinder for rust, dents, gouges and leaks. Cylinders that show signs of wear or leakage should not be used and may need to be replaced even within the cylinder's recertification date.

2.Store cylinders in a secure shelf or cage, ideally away from exits, stairs, entrances, and crowded areas. The facility's LPG supplier can help determine the best location for the cylinders. The cylinders can be placed horizontally with the pressure reducing valve in the highest position, and the operator should use appropriate lifting techniques when handling the cylinders.

Close the service valve on the cylinder when not in use. This helps prevent potential injuries around the internal combustion engine as well as accidental fuel loss.

Fix the pressure relief valve on the cylinder. The operator should check that the relief valve fitting is approximately 180 degrees from the positioning pin of the forklift truck.

The LPG industry has specific procedures in place to support businesses operating with LPG power equipment, including assistance from LPG suppliers across the country. LPG suppliers can provide additional safety support in a number of ways. For starters, they can help workers determine the most suitable location for the gas cylinder, so as not to interfere with the workflow. They can also inspect cylinders each time they are replaced, stop cylinders that are damaged in use, and repair and replace worn valves and O-rings as needed. LPG suppliers also strive to ensure that all employees understand how to safely install LPG cylinders on their forklifts, and some LPG suppliers have also provided additional safety training opportunities for forklift customers. Although there is no safety support and training in the country, it is more important to keep in mind the above safety tips.

LPG is safe and clean. Regardless of the energy of the forklift, it is important for equipment managers and forklift operators to regularly check and follow proper forklift safety procedures. We hope that our safety tips can arouse your attention and improve your safety awareness.