Safety first, NEOlift is here to help you

Nov 30, 2023To help ensure proper operation of forklifts, NEOlift has compiled a quick reference guide for operators of material handling equipment. With detailed information on forklift safety as well as on-site support and training to ensure compliance with health and safety regulations, this guide applies to all types of forklifts such as electric forklift and IC forklifts.

(1) Only qualified forklift operators

● Only trained, authorized and licensed employees are allowed to operate material handling equipment.

(2) Wear the right clothes

● Operators should dress appropriately - the correct safety equipment should be worn at all times, including high visibility jackets, safety shoes and hard hats.

● Keep in mind that loose clothing may get stuck on the forklift or may interfere with the controls.

(3) Equipment inspection

● Material handling equipment should always be thoroughly inspected and daily checked before starting work, and the shift supervisor should be notified if any problems are found.

● The equipment operating instructions in the operating manual should always be followed.

● The equipment in need of repair shall not be operated, and repair and maintenance shall only be carried out by qualified technicians, such as the supplier's service engineer.

(4) Start work

● Never operate material handling equipment with wet or greasy hands or shoes, as they may slip off the controls and cause accidents.

● Always use the provided steps and handrails to load and unload equipment.

● Before starting work, make sure to find a comfortable operating position and that all controls are within reach. Armrests, seat positions and mirrors should be adjusted correctly, and seat belts should always be worn.

(5) Operating environment

● Comply with all work site rules, regulations and restrictions and operate equipment only on designated roads and in designated areas.

● Watch for all warning signs.

● Always keep an eye on the direction of travel and be fully aware of what is happening in the surrounding area.

(6) Drive at a safe speed

● Always operate the equipment within the specified speed limit.

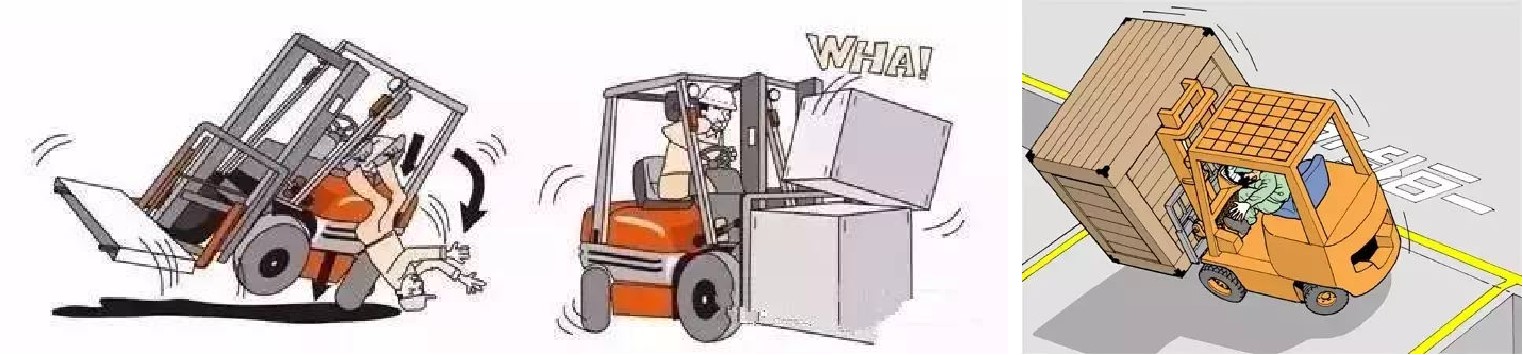

● Drive slowly when turning or turning, as the speed and sharpness of the turn may cause a toppling.

● Do not suddenly stop, start, turn or change direction.

(7) Avoid danger

● Avoid collisions, holes, loose materials, and be extra careful when the floor is slippery.

● Do not drive over objects such as pieces of wood scattered on the ground, as doing so may cause the load to shift or loss of control of the equipment.

● Reduce equipment speed and use horns around corners, exits, entrances, stairs, doors, sidewalks, and near other employees.

(8) Safe operating distance

● Do not operate equipment near other equipment in use unless absolutely necessary

● Keep a safe distance from other devices in case they move in unpredictable ways.

● Always have enough space to park safely.

(9) Load stability

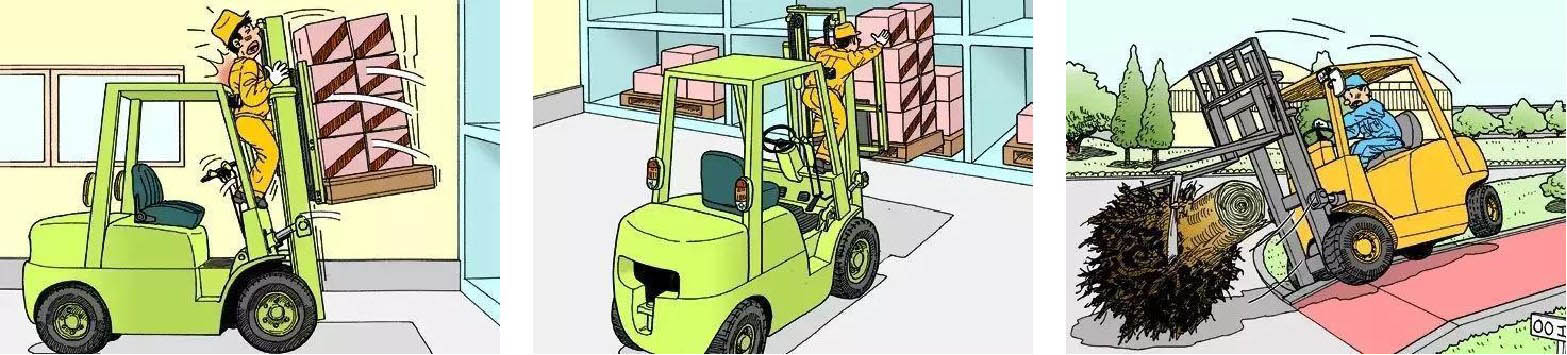

● Handle loads carefully and carefully check their stability and balance before raising, lowering or removing them. Falling loads can lead to injuries and Damaged.

● Tilt the load back and drive the fork as low as possible, which will increase the stability of the equipment in operation.

● Do not drive the fork higher than the floor, or turn the fork in an elevated position or tilted forward.

● When lifting, lowering or stacking the load, please pay attention to the obstacles above.

● Pay attention to the possibility of falling goods when stacking.

(10) Maintain clear visibility in all directions

● Close to the floor to carry the load provides a good front view.

● Operate equipment in reverse when load limits visibility, except when going up a ramp.

● Ensure that the forklift door frame or pallet top can be clearly seen when placing the load.

● When reversing, ensure that the fork is fully tilted back and that the load is securely secured before leaving.

●If visibility is still hampered, be sure to stop and confirm that it is safe to continue. In these cases, surveillance or assistants may be needed.

(11) Correct equipment use

● Do not allow other people to ride the device unless a second seat is installed. Forklifts, for example, are designed to carry loads, not people.

● Do not use forklifts to transport personnel. If you must lift people, use only securely attached work platforms and cages and follow the appropriate operating instructions.

(12) Restricted areas

● No one is allowed to stand or walk under loads, lifting devices or accessories, as the load may fall and cause damage to anyone standing below Serious injury.

● Never place your hands or feet on the beam of the forklift mast, as lowering the mast with your hands or feet on the forklift mast can cause serious injury.

(13) Driving on ramps

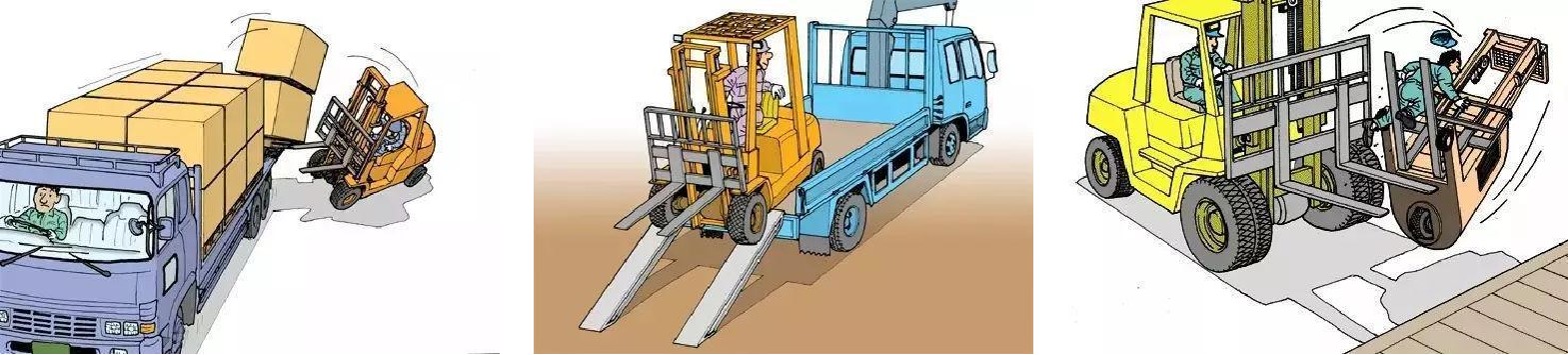

● Remember to drive gradients forward up and backward down, especially when carrying loads.

● Do not load or unload on ramps or make turns.

(14) Ensure load safety

● Do not lift or move unsafe or unstable loads.

● Make sure the load is properly stacked and positioned on both forks.

● Stack goods on pallets or slide safely and correctly.

● If needed, use ropes or lanyards to secure the load.

● When moving long, high or wide loads, operate the equipment more carefully.

● Be aware of other people or obstacles while driving.

(15) Overload is strictly prohibited

● Do not use the fork tip as a lever to lift heavy objects.

● Do not use the fork tip to push the load or use the tilt cylinder to pull the load.

● Do not overload the equipment or add extra weight to the counterweight of the forklift.

● Know and never exceed the capacity of the device and any accessories in use. Overloading the equipment can cause the rear wheels to lift off the ground and can cause

● Equipment tip over, resulting in injury to personnel or damage to equipment or goods.

(16) Evenly distributed load

● Do not lift or move the load unless both forks are completely under the load.

● Do not use one fork to lift the load.

● Use trays and skateboards suitable for the load weight.

● Do not use damaged or rotten pallets or chutes.

(17) Special load

● Take extra care to ensure that round, tall, long or wide loads are balanced and firm.

● Turn and work slowly to prevent the load from moving.

● When maneuvering space is limited, ask for help and make sure you follow the signals given by your assistant.

(18) Observe changes in the operating environment

● Pay attention to all warning signs, especially those on the maximum allowable floor load and headroom height, which may be affected by the workplace Different.

● When entering and leaving the building, please pay attention to the load of the equipment, the height of the mast and the roof guard, especially the forklift.

● Be careful when operating equipment on loading platforms or ramps, keeping a safe distance from the edge, as equipment can tip over and result in injury or loss of load Loss.

● Do not operate equipment on bridge plates unless they can support the weight and load of the equipment.

(19) Refueling and charging the forklift

● The device can only be charged or refueled at a specially designated location.

● Always turn off the device when charging or refueling.

● The refueling of engine powered forklift trucks should be carried out in an area with good ventilation, no spark and no flame.

(20) End of operation shift

● Always park equipment in designated or authorized areas.

● Lower the fork completely to the floor and apply the parking brake.

● Turn off the device and unplug the key.